-

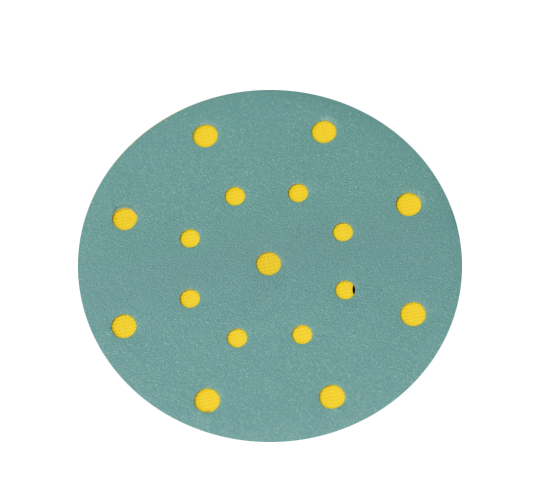

Abrasive Paper

Usually made of various abrasive grit on base paper. According to different abrasive materials, there are a variety of emery paper, artificial emery paper, glass sandpaper and so on. Sandpaper (wood sandpaper) is used to polish the surface of wood and bamboo. Sandpaper Water sandpaper (water sandpaper) is used to polish the surface of metal or non-metallic workpieces in water or oil. The base paper was all made from unbleached sulfate wood pulp. The paper is strong, abrasion-resistant and folding-resistant, and has good water resistance. An abrasive such as glass sand is adhered to a base paper with an adhesive such as a gum and dried.

- -

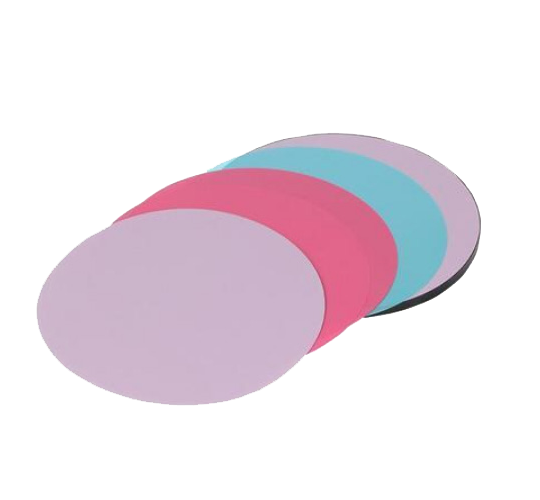

Film abrasive paper

Thin film abrasive paper refers to the use of ultra-precision coating technology to uniformly disperse selected micron or nanometer-level abrasive micropowders (diamond, silicon carbide, aluminum oxide, silicon oxide, cerium oxide, etc.) and high-performance binders, and then apply On the surface of high-strength PET polyester film (POLYESTER), and then processed by high-precision cutting process.

- -

Sponge Abrasive Paper

Sponge sandpaper is suitable for sanding and smoothing. Various materials can be used. Dingsheng sponge sandpaper is made of EVA. It has the advantages of good cushioning, environmental protection, earthquake resistance, heat insulation, moisture resistance, sound insulation, heat insulation, and chemical corrosion resistance The sponge sandpaper sanding process has the characteristics of high production efficiency, good quality of the processed surface, and low production cost.

- -

Stacked Abrasive Paper

Used for grinding and polishing of metal and non-metal, wood products, rubber products, leather, plastic, stone, glass and other materials. During the grinding process, it is continuously peeled off, and then the second grinding layer is exposed for polishing. The process has good acceptability, high work efficiency and low cost.

- -

Precision ground polishing tape

This series of products use advanced precision coating technology to uniformly disperse micro / nano-grade abrasives (diamond, alumina, silicon carbide, silicon dioxide, cerium oxide, etc.) and new polymer materials, then apply High-strength flexible film substrate surface.

- -

Boron carbide

Boron carbide is produced by smelting boric acid and carbon powder in an electric furnace at high temperature. The theoretical density is 2.52 g / cm, the melting point is 2450 ° C, and the micro hardness is 4950 kg / cm. Its extremely high hardness is second only to diamond and cubic boron nitride. Due to its high temperature resistance, acid and alkali corrosion resistance, high strength, high chemical stability, high elastic modulus, and low specific gravity, it has become an ideal material for many industries.

- -

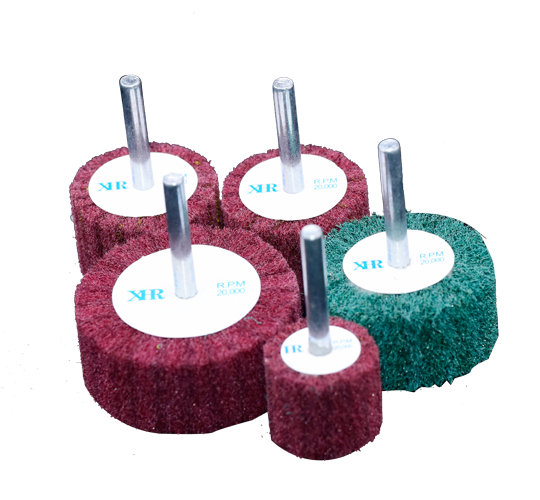

Grinding wheel with handle

The elasticity of PBT wire is better than that of nylon brush wire, but the abrasion resistance is not as good as 610. The performance of PBT is soft. It is suitable for cleaning and decontamination of fine parts, such as automobile surface cleaning.

- -

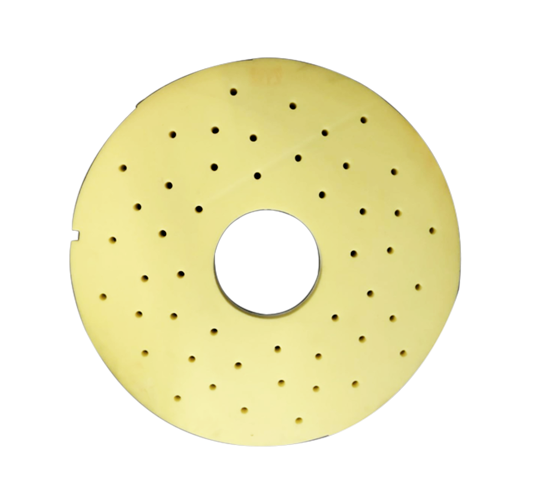

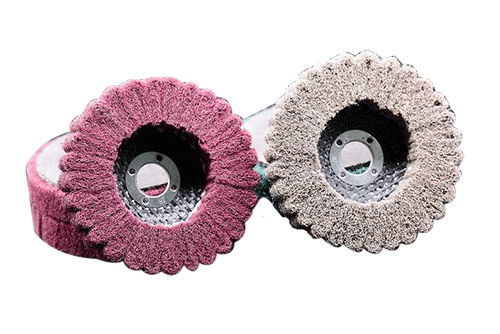

Grinding wheel

The grinding wheel can effectively dissipate the heat generated in the grinding layer during grinding, improve the grinding performance, and also improve the finish on the surface to be ground. The grinding wheel includes a large number of abrasive particle attachments having a desired size and shape, and each abrasive particle attachment has a large number of abrasive particles on its surface. These abrasive particle attachments are to be installed in a closely stacked relationship in a radial direction. On the outer circumference of the ring, the abrasive layer formed by laminating the abrasive particle attachments is provided with different density portions distributed at a desired interval in the circumferential direction to improve the grinding function at the hig...

- -

Drawing wheel

Wire drawing wheels, which are mainly installed on hand-held power tools for grinding and polishing the welds, burrs, chamfers, surface rust removal and surface polishing of various types of metal and non-metal parts. Compared with fixed resin abrasive wheels With one-time grinding and polishing, shortening the operating time, saving grinding costs, improving grinding efficiency, high abrasive self-sharpening, high utilization rate, air-cooled cooling does not hurt the surface, easy surface quality control and high cost performance, reducing operator fatigue and increasing machinery Therefore, it is widely used in various industries or fields of manufacturing.

-