-

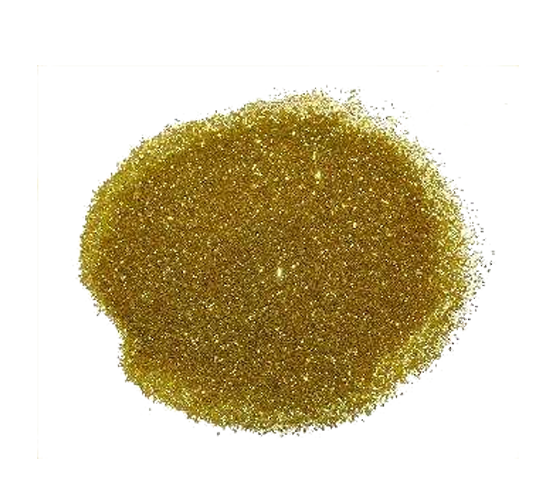

Single crystal diamond powder

Single crystal diamond powder has a large output and a wide range of applications. The diamond powder is generally referred to as single crystal diamond powder in the industry. The single crystal diamond powder is a synthetic diamond single crystal abrasive grain by the static pressure method. After crushing and shaping, it uses superhard materials. Special craft method production. Diamond powder has high hardness and good wear resistance, and can be widely used in cutting, grinding, drilling, polishing and so on.

- -

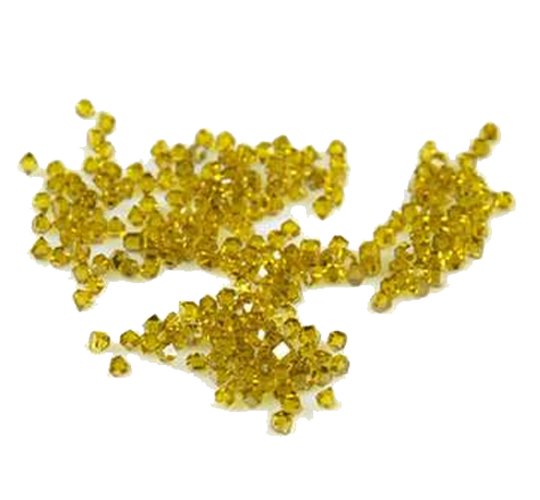

Polycrystalline Diamond Powder

Polycrystalline diamond powder is made from graphite using a unique directional blasting method.The blasting shock wave accelerates the flying metal sheet and impacts the graphite sheet, which results in the conversion of graphite into polycrystalline diamond. Its structure is very similar to the natural Carbonado. It is formed by combining unsaturated bonds and has good toughness.

- -

Polycrystalline Diamond Powder

Polycrystalline diamond, also known as polycrystalline diamond, polycrystalline diamond. Guo Ruisheng's polycrystalline diamond is synthesized by detonation method, and its grain crystal structure is very similar to the natural Carbonado, and it is combined into a polycrystalline structure through unsaturated bonds.

- -

Ceria

It is mainly used as a glass decolorant, glass polishing powder, and also a raw material for the preparation of metallic cerium. High-purity cerium oxide is also used to produce rare earth luminescent materials. Insoluble in water, soluble in strong inorganic acids. Used as decoloring, clarifying agent, high-grade polishing powder for glass, and also used in ceramic electrical, chemical and other industries. The packaging specifications are also different. Up to one kilogram.

- -

Alumina polishing liquid

The polishing liquid is a water-soluble polishing agent that does not contain any sulfur, phosphorus, and chlorine additives. It has good degreasing, rust prevention, cleaning, and gloss enhancement properties, and can make metal products exceed the original gloss. Product performance is stable, non-toxic, and no pollution to the environment.

- -

Silicon dioxide polishing fluid

A silica-based CMP polishing liquid, characterized in that the polishing liquid contains 10-50% by weight of nano-silica abrasives, 0.1-10% of a dispersant, and 0.1-10% of a wetting agent. 0.1 to 10% of the chelating agent, 0.01 to 1% of the pH regulator, the rest is deionized water.

- -

Diamond polishing liquid

Diamond polishing fluids include three different types of polishing fluids: polycrystalline, single crystal and nano. Diamond polishing liquid is composed of high-quality diamond powder, composite dispersant and dispersion medium.

-